Custom NFC device and tag emulator design

Our client needed a bespoke solution to allow guests to check into events and clubs using their phones and on-board NFC functionality. Available NFC hardware solutions didn’t provide the level of functionality they required to interface with their software and back end server. We created a fully bespoke, industrial design, PCB design and firmware, from the first pencil stroke to the delivery of fully assembled and tested units.

IoT

What we did

- Concept design

- User interface design

- Electronic design

- Custom NFC antenna design

- Firmware development

- Mechanical design

- Industrial design

- Design for manufacture

- Tooling

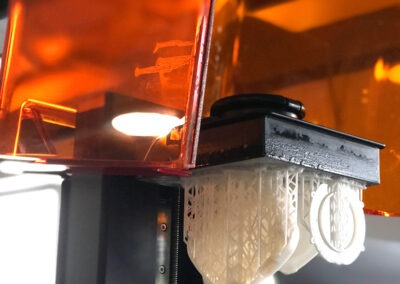

- Mechanical prototypes

- Electronic prototypes

- EMC testing

- Supplier introductions

- Supply chain management

- Delivered to client fully assembled and tested

We designed everything, from the initial concept and user interactions, through to the custom electronics and firmware. Our expertise cut out the complexity and risk for our client and delivered a simple on demand service – a 25 unit minimum order and lead times as short as 2 weeks for fully assembled and tested devices.

This was our client’s first foray into the world of physical products and hardware – their core business is membership and CRM software for corporates. Their requirement was to have a physical layer with which members and guests of their customers’ businesses could interact directly with their software systems, using their own phones and their NFC capabilities.

A small team of designers and engineers at Ignitec rapidly created a vision and brought the NFC device to life with sketches, CAD models and hardware prototypes.

Once the vision was created, we developed every part of the technical design and built a complete supply chain to give our client a truly turnkey solution. Through our expansive network and established relationships with our manufacturing partners, we delivered a supply solution which allowed our client to be extremely agile and take less risk. We cut out all of the complexity of manufacture and supply chain management for our client and delivered a simple service – a 25 unit minimum order and lead times as short as 2 weeks for fully assembled and tested devices.