Ignitec’s Comprehensive Mechanical Engineering Service

With Ignitec’s Mechanical Engineering Service, gain the confidence in your product designs you’ve been looking for. Our experienced team delivers robust solutions addressing your product performance and durability needs.

The Ignitec advantage

Our multi-disciplinary team, experienced in Mechanical Engineering Service, ensures rapid, end-to-end solution for your product design challenges.

Why use our Mechanical Engineering Service?

- Expert team with a strong track record

- Comprehensive solutions from concept to launch

- Proven ability to reduce product failures

- Tailored support on a project basis or ongoing

- Extensive experience across various industry verticals

Ignitec’s Mechanical Engineering Service offers an integrated solution to businesses facing challenges with product performance and reliability. We understand the gravity of mechanical failures in products and the potential negative impact on your reputation and bottom line. That’s why we leverage our more than a decade of experience in mechanical engineering to provide solutions that instil confidence in your designs.

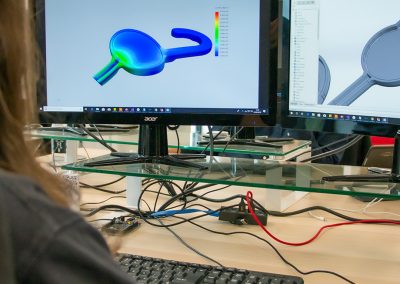

3D CAD Design and Mechanical Simulation

With a deep understanding of your challenges, we employ advanced tools like 3D CAD Design and Mechanical Simulation to create and test robust product designs. Our team of skilled engineers works meticulously, ensuring that each design is optimised for functionality and durability.

Finite Element Analysis (FEA) and Fluid Simulation

To further assure the quality of our designs, we utilise Finite Element Analysis (FEA) and Fluid Simulation. These methodologies enable us to predict how your product will react to real-world forces, vibration, heat, and other physical effects. By doing so, we help mitigate the risk of product failure before your product even hits the market.

Physical Prototyping and Testing

Our Mechanical Engineering Service doesn’t stop at theoretical analysis. We bring designs to life through Physical Prototyping and Testing. This real-world assessment allows us to confirm the product’s performance and make necessary adjustments before final production.

Design Optimisation

Finally, we focus on Design Optimisation. With a keen eye for detail, our team refines the product design to improve performance, reduce failure rates, and possibly even result in cost and weight savings.

All these activities form part of a robust, iterative process of design, testing, and optimisation. This comprehensive approach has enabled us to deliver improved product performance, reduced failure rates, and cost savings across various industry verticals for more than a decade.

CageEye

Enhancing Fish Feeding Efficiency in Harsh Underwater Environments with CageEye

CASE STUDY | SUBSEA

Forensic autorotator

Automated fingerprint development on glasses and bottles

CASE STUDY | FORENSICS

Oscarline

Man-overboard recovery system

CASE STUDY | MARINE SAFETY

Find Out How We Can Help – Contact Us for Expert Guidance on Your Next Project

Years established

Projects delivered

Clients served

Get started

Our expert team is here to help with all of your electronic design, software and mechanical design challenges. Get in touch with us now for more information and a free review of your requirements.