Design and Manufacturing of Environmental Monitoring Technology

Faced with the need for a more efficient, cost-effective solution to monitor glacial melting, Aarhus University approached Ignitec. In just a few weeks, we delivered 25 fully integrated, tested and ready-to-use water level sensors, streamlining their research process with our expertise in the design and manufacturing of environmental monitoring technology.

Outcomes

With Ignitec’s assistance, Aarhus University Department of Environmental Science was able to effectively monitor the health and melting of glaciers. The rapid design and manufacturing of this environmental monitoring technology saved extensive manual assembly time and significantly reduced costs.

What we did:

- Identified the required outputs for a new fully integrated system

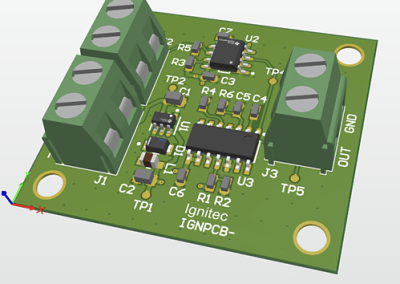

- Designed a piece of low cost sensing hardware to deliver these outputs

- Water level is measured by capacitance and the device is powered by a 9v battery

- Manufactured, tested and supplied 25 units within a short timeframe

The Challenge:

Aarhus University Department of Environmental Science conducts critical research on environmental chemistry, atmospheric physics, environmental economics, and much more. Their work has far-reaching implications for our understanding of the environment and our impact on it. One of their challenges was monitoring the health and melting of the northern hemisphere’s glaciers. This involved measuring water levels in boreholes, a task requiring reliable, precise technology.

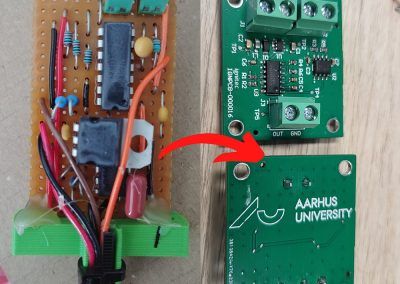

They had a legacy system that converted a water level logging probe’s readings into voltages recorded by a data logger. The system was hand-assembled by a retired technician, whose absence posed a challenge in terms of building and maintaining these circuits. They needed a robust, cost-effective, and scalable solution, ready for deployment in a challenging environment.

What we did:

After understanding the required outputs and the existing data logger’s functionality, Ignitec set out to design a new, fully integrated system. Our multi-disciplinary team leveraged their extensive knowledge in electronics, software, and design to create a device capable of delivering accurate results under the harsh conditions of the northern hemisphere’s glaciers.

We managed to streamline the previous, complex process by integrating all the functions into one piece of hardware. This hardware not only allowed for easy manufacturing at low volumes but also had the potential to be produced at higher volumes if necessary. Within weeks, we supplied Aarhus University with 25 fully tested, ready-to-use boards.

Results:

The results of our work were immediately tangible. Aarhus University could proceed with their critical research without the worry of circuit construction and maintenance. The new technology allowed for accurate data collection, with lower costs and faster turnaround times. The delivered units were robust, ready to face the challenging environment, and required minimal weatherproofing. The university could now focus on their research, knowing their technology needs were well catered for by Ignitec.

Find Out How We Can Help – Contact Us for Expert Guidance on Your Next Project

Years established

Projects delivered

Clients served

Get started

Our expert team is here to help with all of your electronic design, software and mechanical design challenges. Get in touch with us now for more information and a free review of your requirements.