End-to-End Subsea Hardware Solution: A Case Study with Mesh Global

Facing obsolescence and component shortage issues, Mesh Global needed a reliable partner for a swift hardware redesign. Ignitec’s Subsea Hardware Solution not only delivered an updated and robust product, but also future-proofed their design, contributing to cost savings and increased sales.

Client: Mesh Global

Outcomes

Through Ignitec’s Subsea Hardware Solution, Mesh Global not only overcame their component obsolescence and supply issues, but also significantly enhanced their business sustainability by future-proofing their design. This strategic approach led to increased sales, realised cost savings, and ensured the delivery of robust and reliable products to their customers.

What we did:

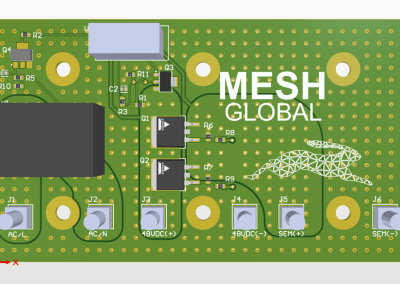

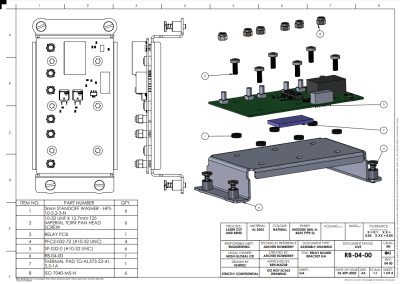

- Redesigned PCB incorporating readily available components, providing a robust solution to the obsolescence issue.

- Delivered dual redundancy in the design for increased safety and reliability.

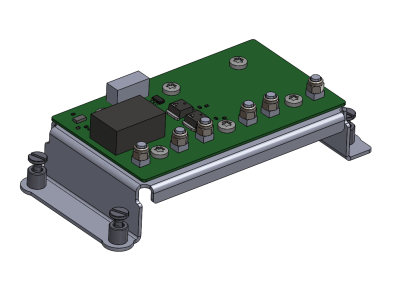

- 100 units of the new hardware, along with mounting brackets, supplied in under 8 weeks.

- Provided upfront costs and timescales, allowing effective customer communication and increased sales.

- Realised cost savings and future-proofed design, enhancing long-term business sustainability.

The Challenge:

The global pandemic brought unprecedented supply chain disruptions, and businesses worldwide had to confront significant challenges. Mesh Global, an experienced systems integrator, faced a particularly daunting task – a looming obsolescence of components in their older hardware. With a scarcity of supply and a mounting demand for their products, Mesh Global needed a quick, reliable, and robust solution to keep their operations going and their customers satisfied.

What We Did:

When faced with a challenge, Ignitec delivers. Harnessing the strengths of our multi-disciplinary team, we addressed Mesh Global’s problem head-on. A comprehensive redesign of the problematic control PCB was initiated, replacing the obsolete relays with generic high-power MOSFETs and other easily substitutable components. To ensure increased safety and reliability, dual redundancy was incorporated into the design, offering Mesh Global a robust solution to their problem. By utilising readily available components, the redesigned hardware was effectively future-proofed, capable of enduring future supply chain disruptions.

Results:

Our Subsea Hardware Solution delivered more than just a fix to a pressing issue. It served as a foundation for future growth and sustainability for Mesh Global. With the updated and robust product design, Mesh Global could meet their existing order commitments and effectively communicate with their customers, resulting in increased sales. Furthermore, the redesign future-proofed their product, promising easy and cost-effective updates as required in the future. As a result, Mesh Global experienced substantial cost savings and boosted their business sustainability in the long term.

Find Out How We Can Help – Contact Us for Expert Guidance on Your Next Project

Years established

Projects delivered

Clients served

Get started

Our expert team is here to help with all of your electronic design, software and mechanical design challenges. Get in touch with us now for more information and a free review of your requirements.